(1) Pre-supercharger mixing technology, gas and air are inhaled at the same time in the compressor to apply to low-pressure gas.

(2) Lean combustion technology, the use of the world's advanced gas control system control system to accurately control the air-fuel ratio, to achieve high-altitude fuel ratio, to achieve lean combustion.

(3) Single-point gas injection and air-fuel ratio closed-loop control technology to achieve closed-loop control of air-fuel ratio (λ). The engine can automatically adjust the amount of air and gas according to the requirements of different working conditions and different speeds in a timely manner, so that the engine can run in a better state.

(4) Reliable inlet and exhaust system design, the selection of high pressure ratio, large flow supercharger, increase the flow area of the intake pipeline, improve the intake efficiency.

(5) The use of German technology rate, low resistance intercooler and plate oil cooler to improve cooling efficiency and increase the cooling area of air and lubricating oil.

(6) The selection of high-energy, high-reliability IC-16 ignition system, so that the engine cylinder combustion is more stable and uniform.

(7) The stable and intake system ensures the effective play of the power of the unit

(8) Effective protection of exhaust system to prevent thermal radiation and safety hazards

(9) Reasonable oil lubrication system to ensure low fuel consumption

(10) Security - four lines of defense to ensure the safety of gas pipelines

(11) The unit adopts advanced factory test and quality control

Control system:

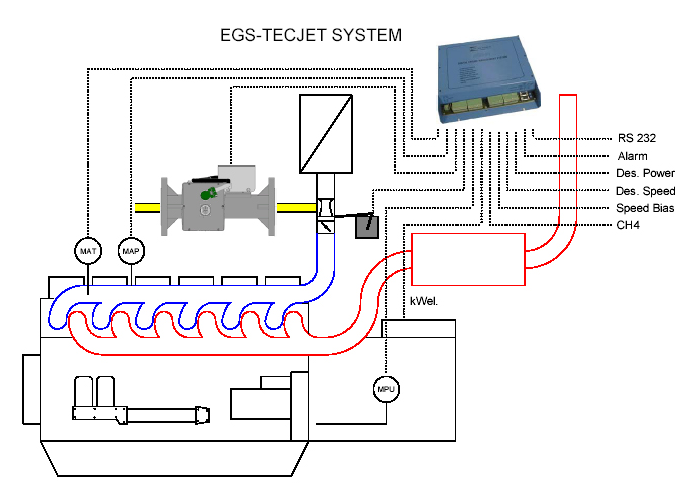

"Jicai" brand 16V biogas generator sets use the world's more advanced Woodward-EGS air-fuel ratio control system, Tecjet control valve and mixer, electronic governor and other gas intake control system, the current well-known brands such as Cutler, Waxha and other biogas units, such as WOODWARD control technology. Strong adaptability to gas concentration changes and pressure changes.

EGS is a full computer intelligent, high precision gas intake control system, which can realize real-time monitoring of unit parameters through computer interface. Its information input system includes speed sensor, λ sensor (unit calibration), power sensor or torque signal sensor, methane sensor, two inlet pressure sensors and one inlet temperature sensor, These sensors transmit signals such as changes in landfill gas concentration, speed, power (or torque), and oxygen content in exhaust gas (for calibration purposes) to the EGS controller in a timely manner during engine operation. The EGS controller comprehensively processes the above information, calculates the gas amount required for better operation of the engine, and transmits the information to the Tecjet control valve, which controls and adjusts the gas intake volume to achieve the purpose of controlling the better air-fuel ratio. By controlling the WOODWARD-ProAct actuator to control the flow of the mixture, the engine speed is controlled within the calibration range.

EGS control module and related auxiliary equipment constitute a true closed loop electronic control system. The application of air-fuel ratio closed-loop control technology makes the combustion of the gas unit more reasonable, and the air-fuel ratio mixing can be automatically adjusted according to the change of biogas concentration, so the unit runs more smoothly and the control is more accurate.

Technical characteristics

Technical characteristics

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone